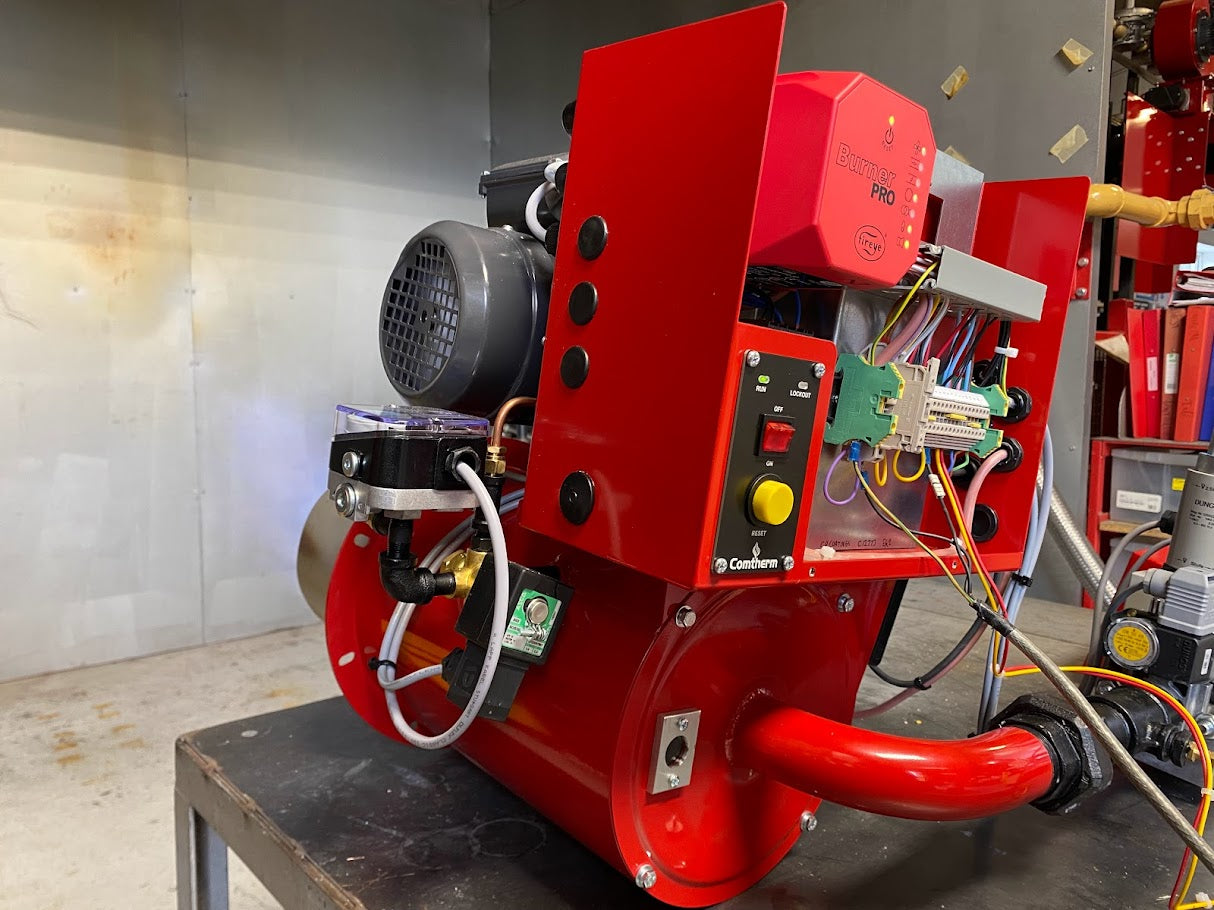

Introducing the EK Burner – a fully packaged combustion solution featuring integrated electrical controls and a pre-assembled valve train. Ideal for a diverse range of processes, such as powder coating lines, cure ovens, spray dryers, and more.

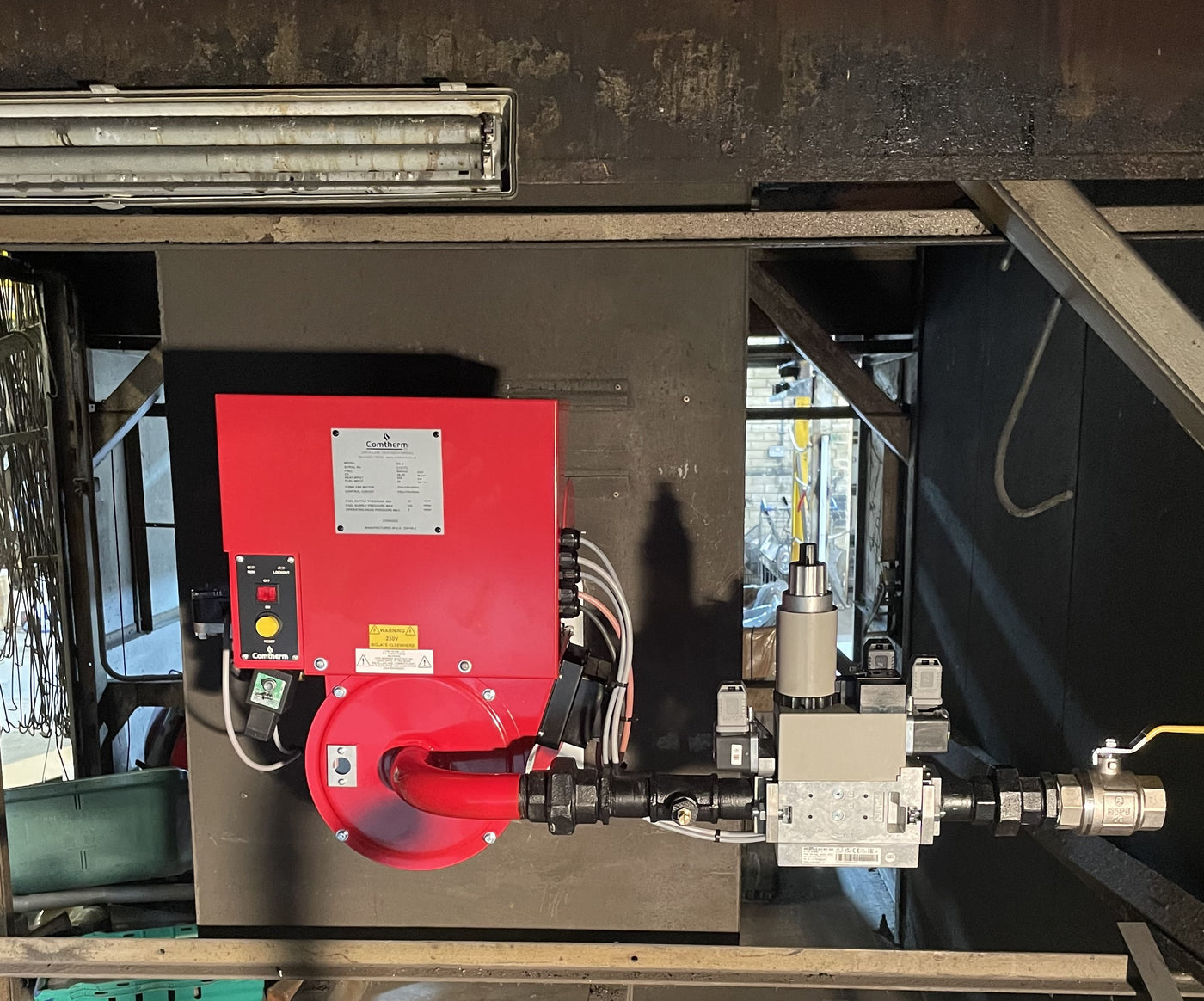

With its sleek and compact design, the EK burner seamlessly integrates into virtually any application. The versatile design allows you to choose from multiple control options, including on/off, high/low, and modulating gas.

The innovative 'Cone' design of the EK ensures superior heat distribution compared to other concentrated flame designs. Maintenance is a breeze, thanks to our careful design process, making fault-finding and repairs remarkably easy.

At Comtherm, adapting to challenges is at the core of our business. With over 40 years of industry experience, we understand the constraints of space and design. The EK burner can be customized to accommodate various orientations and valve train configurations, addressing your unique needs.

Contact our team for more information on how the EK Burner can elevate your processes.

The EK burner is a robust industrial package burner suitable for direct firing in many applications where high turndown, short flame and low emission performance is required.

The burner’s compact dimensions, combined with its reliability and low cost make the unit ideal for many industrial process applications. The unit is simple and safe to operate. All units are pre-fired and fully tested before leaving our works.

The burner has been successfully used in many industries including food processing, metal finishing, textiles, ceramics and glass.

EK Technical Features

-

Typical Applications

-

Turndown

30:1 Max

-

Burner Duty

-

Gas Supply Pressure

20 mbar

-

Fuel Types

-

Flame Length

1250mm (max)

Downloads

Frequently Asked Questions

Technical

Can the EK burner run on all fuels?

Can the EK burner run on all fuels?

It is suitable for Natural gas and L.P.G however other fuels can be accommodated but, please speak to our technical sales

Can it be modulating gas and air?

Can it be modulating gas and air?

No the EK burner is design for on/off - high/low and modulating gas only. Please look at our PC range for modulating gas and air.

Do you offer 110v Control?

Do you offer 110v Control?

Yes we build EK's with 110v and 230v control voltages.

Can you change the handing of the burner?

Can you change the handing of the burner?

Yes we can accommodate various different valve train handing's and burner casing orientations.